Cellulose From Water Hyacinth As Acrylamide Adsorbent In Frying Oil

Abstract

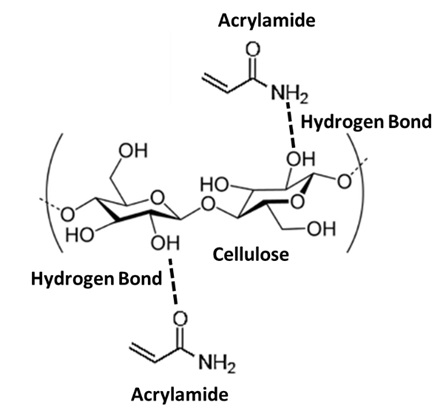

Cooking oil frequently used by the community is palm oil. When heated repeatedly, this oil can produce acrolein, a compound that contributes to the formation of acrylamide. Water Hyacinth cellulose contains -OH groups capable of binding to acrylamide. The purpose of this study was to determine the effect of adding Water Hyacinth cellulose as an adsorbent and to evaluate the impact of soaking time and cellulose weight on acrylamide levels. The analysis was conducted using HPLC, with a mobile phase consisting of methanol and 0.1% phosphoric in a ratio of 5:95, at a flow rate of 1mL/min; the volume of the injected sample was 20 µL. Acrylamide in oil was identified at a retention time of 4.700 minutes. The regression equation obtained from the acrylamide calibration curve is y=229.52 x + 10.472 with a correlation coefficient (R2) of 0.9988. This study concluded that soaking for 24 hours can reduce acrylamide levels by 69.13%, and using 6 grams of cellulose can reduce acrylamide levels by 75.15%.

Downloads

Copyright (c) 2024 Winda Trisna Wulandari, Mulya Tri Sugiharti, Gatut Ari Wardani

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish with this journal agree to the following terms:

- Copyright on any article is retained by the author(s).

- The author grants the journal, the right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgment of the work’s authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal’s published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.

- Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work.

- The article and any associated published material is distributed under the Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

_copy1.png)