Calcinated Ferronickel Slag as Catalyst In Biodiesel Synthesis from Cooking Oil

Abstract

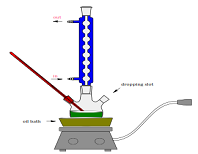

Ferronickel slag is a byproduct of the nickel ore smelter factory that is typically dumped in an open area and is detrimental for the environment. The research objectives are to examine ferronickel slag potential as catalyst in producing biodiesel. Ferronickel slag was prepared by milling followed by sieving 200 meshes and calcinated at 900 ºC. The next step was to evaluate the calcinated slag using XRF, which revealed that the major components were, in order, Si (49.47%), Fe (36.09%), Ca (7.12%), Cr (3.01%), and Mn (2.28%). Slag that has been calcined and utilized in the transesterification of cooking oil as catalyst in three necked flask with oil to methanol ratio is 1:9, reaction times (1, 2, 3 hours) and temperatures (70, 90, 110 oC). Then, the product were tested for water content, density, viscosity, acid number, free fatty acids, total glycerol, percent of methyl esters according to SNI 7182-2015. FTIR showed the presence of peaks at 1743.65 and 1157.29 corresponding to C=O and O-CH3 functional groups.

Downloads

Copyright (c) 2024 Boy Chandra Sitanggang, Neny Rasnyanti M. Aras

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish with this journal agree to the following terms:

- Copyright on any article is retained by the author(s).

- The author grants the journal, the right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgment of the work’s authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal’s published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.

- Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work.

- The article and any associated published material is distributed under the Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

_copy1.png)