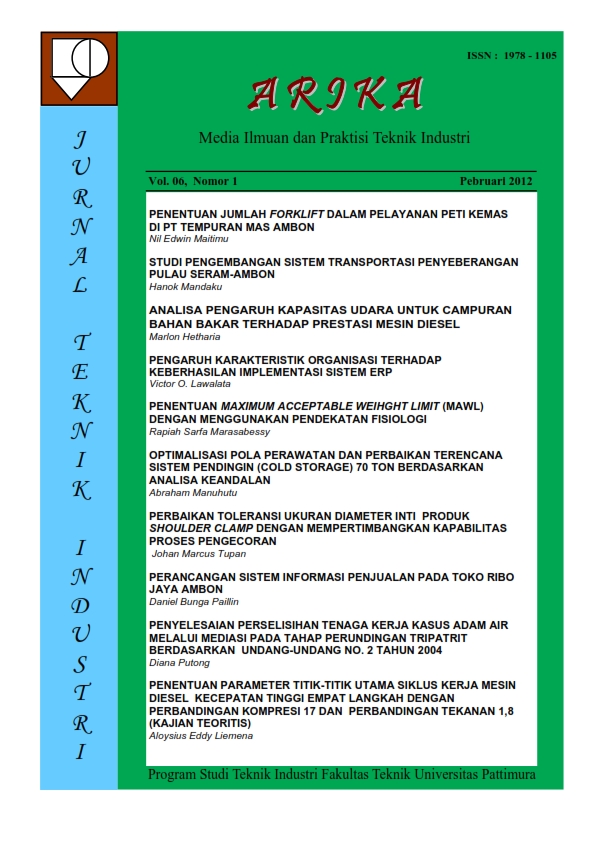

Perbaikan Toleransi Ukuran Diameter Inti Produk Shoulder Clamp Dengan Mempertimbangkan Kapabilitas Proses Pengecoran

Abstract

The design tolerance as one of the characteristics of quality is a critical stage in the design process and product. Reflects the absence of economies of size tolerance manufacturing process. Performance of the production process can be measured by indices of process capability. This study aims to redesign the new specification limits (tolerance) diameter core (core) products based on the ability of the clamp Shoulder-owned company, Tolerance and Tolerance Standard Casting. The analysis show that the casting process is currently capable of producing the products according to specifications defined by the index Cp = 0.65; Cpk = 0.50; CR = 1.55 and Cpm = 0:59. Based on the performance of the casting process is proposed an alternative six shoulder clamp diameter tolerance are 23:50 +- 0.80 mm, 0.82 mm +- 23:50, 23:50 +- 23:50 +- 1:20 mm 1:26 mm, 1.70 mm +- 23:50 and 23:50 +- 2:40 mm

Downloads

An author who publishes in the ARIKA Jurnal agrees to the following terms:

- The author retains the copyright and grants ARIKA journal the right of first publication of the work simultaneously licensed under the Creative Commons Attribution-ShareAlike 4.0 License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- The author is able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book) with the acknowledgment of its initial publication in this journal.

- The author is permitted and encouraged to post his/her work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of the published work (See The Effect of Open Access).